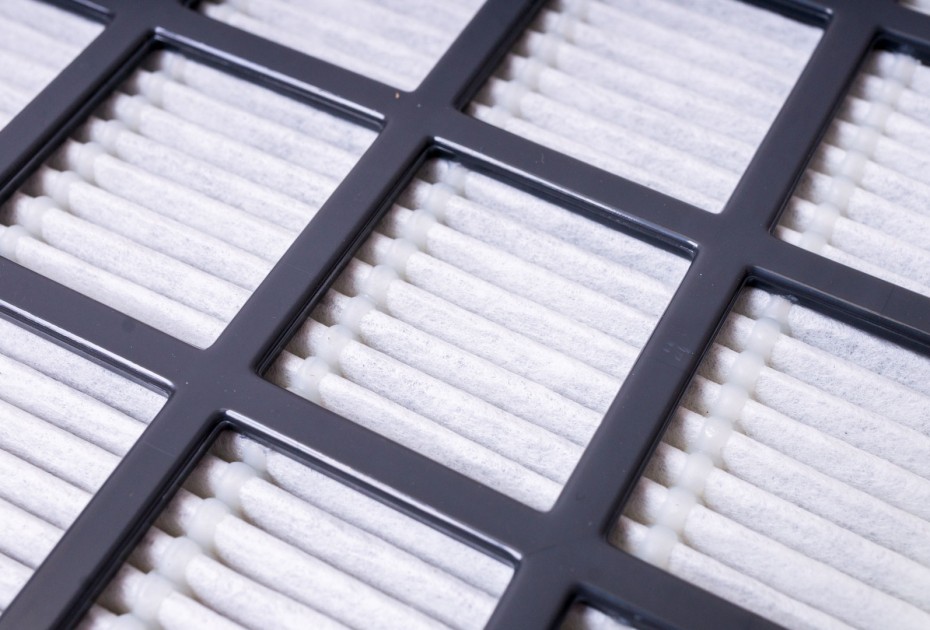

Air filters are physically simple but technically complex devices, controlling air purity in a wide range of industrial and domestic processes from computing and telecommunications to personal protection and medical care.

Stricter environmental legislation combined with amplified health concerns means that there is a continuous demand for clean air, resulting in increased efforts to improve the quality and performance of air filters. At the same time, the need to reduce energy consumption at lower costs remains a key area of focus for the majority of manufacturers.

With over 30 years’ experience in the nonwovens industry, our Lowbond™, Lowbond™ Ultra, Meltblown TPU and Meltblown PP filtration fabrics have been designed and engineered in partnership with our customers to create solutions for some of the most demanding applications. Our ability to incorporate a range of additives and to laminate our spunbond and meltblown fabrics to other materials allows us to meet the increasing demands of the filtration industry. We can also design our fabrics to meet customer-specific requirements, so you can be sure that your product or application requirements are always met.

Developed and manufactured in the UK, Lowbond™, Lowbond™ Ultra, Meltblown TPU and Meltblown PP nonwovens provide air filtration devices with excellent chemical resistance, additional functionality, and high air permeability.

We aim to stay at the forefront of research, design, and development, ensuring that we continue to manufacture versatile and high performing filtration nonwovens.

| Electrostatically Charged Meltblown PP Fabrics | English | Download |

| Filter Carriers & Supporting Scrims | English | Download |

| Meltblown PP Fabrics | English | Download |

| Pre-Filters | English | Download |

| Air Permeability Comparison Chart | English | Download |

| Corporate Brochure | English | Download |

| Filtration Brochure | English | Download |

| Filtration Introduction | English | Download |

| Geotextiles Introduction | English | Download |

| Laminate Substrates Flyer | English | Download |