D&L Meltblown fabrics, Meltblown PP, are produced using the most up-to-date manufacturing processes available. The additional line features are control of key process settings for material optimisation, in-line measurement, control of air permeability, bespoke melt additives and colours available for enhanced fabric properties, and thermal flat calendar for in-line lamination.

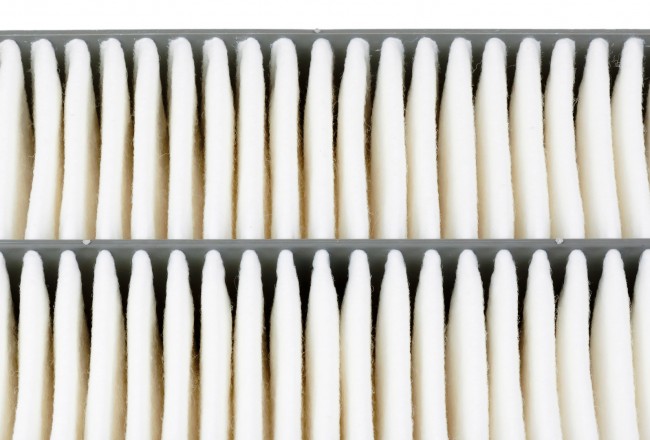

With the capability to produce fine fibres, ideally suited for the filtration of respirable particles, Meltblown fabrics provide air filtration applications with excellent barrier and filtration properties.

Available in weights ranging from 13 – 300g/m2 (PP) and 30 – 200g/m2 (TPU), Meltblown nonwovens are perfectly suited for applications such as industrial respirators, vacuum cleaner bags, automotive cabin filters, and microbiological filters.

Meltblown fabrics also have the following advantages for filtration products:

- Available in widths up to 160 cm

- Available in various colours

- Melt additives to give enhanced fabric properties, such as UV stability and hydrophobicity

- Electrostatic charging of filaments for enhanced sub-micron particle filtration

- In-line measurement and control of air permeability

- In-line thermal flat calendaring

| Meltblown PP Fabrics | English | Download |

| Electrostatically Charged Meltblown PP Fabrics | English | Download |

| Filtration Introduction | English | Download |

| Corporate Brochure | English | Download |

| Filtration Brochure | English | Download |